Taizhou Huangyan Debodi Mold Co., Ltd. was originally Taizhou Huangyan Nuokang Mold Co., Ltd. is located in Huangyan Economic Development Zone, Zhejiang Province. The company has been focusing on PET Bottle preform mold design and research and development can be customized according to customer requirements. Focusing on one-stop service allows customers to avoid post-service problems caused by multiple purchases. Our products are widely used in beverages, food, edible oils, condiments, candies, cosmetics, detergents, medical supplies and other fields. Our products are not only based in China, but also exported to the United States, Europe, South America, the Middle East, Southeast Asia, Africa, etc. countries and regions, and is well-known in many markets at home and abroad.

We have advanced mold processing equipment and strong technical force. We fully use CAD, CAE, and CAM systems to design, shape, and program various bottle preform molds. We have high-end, precision, and cutting-edge manufacturing capabilities. Mold capabilities. In terms of design, we all use CAD, 2D, 3D and other software technologies to meet the needs of various shape designs of plastic products in today's market. We devote ourselves to studying the mold industry, forge every mold and every part with ingenuity, and provide mold solutions for thousands of corporate customers. We have many elite business representatives, professional technical engineers and multiple agencies to provide domestic and foreign customers with business consultation, technical support and after-sales service at any time, and provide one-stop service throughout the entire process of mold design, production and use, saving Save effort and effort. Warmly welcome new and old customers at home and abroad to visit and patronize us.

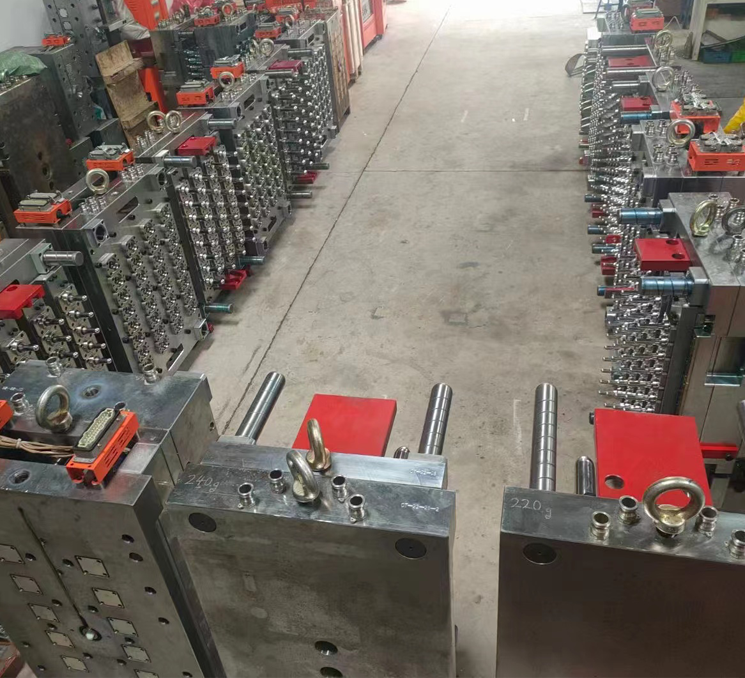

DEBODI Mold's experienced and dedicated workforce specializes in multiple departments, providing mold design and manufacturing services to create unique features for different types of PET plastic preforms. We have a full range of plastic bottle preform mold manufacturing capabilities and manufacture molds in a pleasant working environment.

By analyzing material physical properties and product feasibility, such as wall thickness, degree of deformation, glue feeding position, etc., potential problems can be predicted in advance. Maintain close communication with customers, and understand product functional requirements and precautions from the customer perspective, such as joint line requirements, appearance requirements, etc. Strict design review system and checklist inspection. Before design, during the design structure discussion meeting, designers self-check according to the checklist; after design, they review together with the manufacturing department.

From raw materials to processing to final molding, quality inspection is conducted at every step to detect problems in advance. Each project has a complete set of quality inspection reports for easy traceability, such as appearance requirements, etc. It has accumulated experience in mold development, design, and injection molding in industries such as bottle preforms and bottle caps.

Each project is assigned a project manager who strictly follows the schedule to control the project cycle. Provide weekly progress reports and mold photos for each project to keep customers informed of the status. Mold trial videos are provided online to allow customers to understand the operation of the mold.