Debodi Mold - is a manufacturer that specializes in the design and manufacture of plastic bottle preform molds. It specializes in the research and development of molds. We have many years of design experience and a professional R&D team. We have many customers and Rich success stories. The molds designed and manufactured by our company are of high quality, sturdy and durable. We fully understand customer needs and provide a full range of services. We can also customize high-quality preform molds to meet the individual needs of customers. We cooperate with customers in a serious and down-to-earth manner. , constantly develop innovative technologies and introduce various new equipment to meet customer needs, in order to achieve customer satisfaction and praise for quality and service.

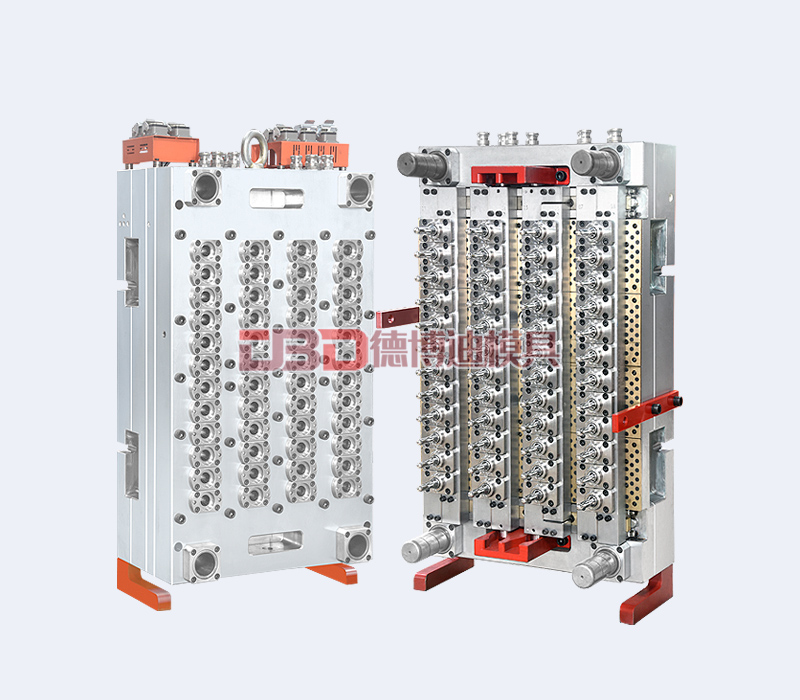

The number of cavities of PET bottle preform mold ranges from 1 to 96;

The number of cavities of PET bottle preform mold ranges from 1 to 96; Rigorous scheme design, mass production after one mold trial

Rigorous scheme design, mass production after one mold trial Quality inspection at every step to detect mass production problems in advance

Quality inspection at every step to detect mass production problems in advance Provide progress reports at any time to let customers know the status at all times

Provide progress reports at any time to let customers know the status at all times  Free customization service, 3D preform sample design

Free customization service, 3D preform sample design The advanced preform structure is designed with reference to European mold styles.

The advanced preform structure is designed with reference to European mold styles.

15258597071

15258597071

DEBODI Mold's experienced and dedicated workforce specializes in multiple departments, providing mold design and manufacturing services to create unique features for different types of PET plastic preforms. We have a full range of plastic bottle preform mold manufacturing capabilities and manufacture molds in a pleasant working environment.

By analyzing material physical properties and product feasibility, such as wall thickness, degree of deformation, glue feeding position, etc., potential problems can be predicted in advance. Maintain close communication with customers, and understand product functional requirements and precautions from the customer perspective, such as joint line requirements, appearance requirements, etc. Strict design review system and checklist inspection. Before design, during the design structure discussion meeting, designers self-check according to the checklist; after design, they review together with the manufacturing department.

From raw materials to processing to final molding, quality inspection is conducted at every step to detect problems in advance. Each project has a complete set of quality inspection reports for easy traceability, such as appearance requirements, etc. It has accumulated experience in mold development, design, and injection molding in industries such as bottle preforms and bottle caps.

Each project is assigned a project manager who strictly follows the schedule to control the project cycle. Provide weekly progress reports and mold photos for each project to keep customers informed of the status. Mold trial videos are provided online to allow customers to understand the operation of the mold.